The Pipe Fabrication Shop Need

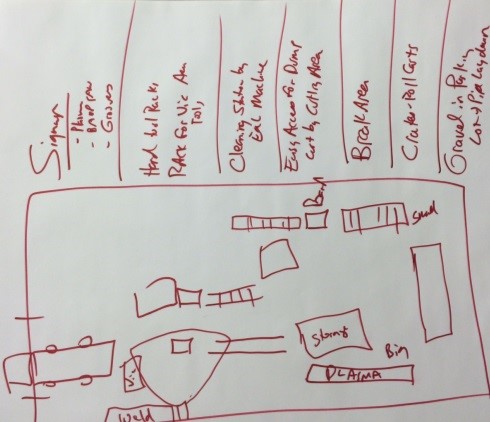

In anticipation of the high demand for prefabricated, grooved, and partially assembled piping for our large downtown skyscraper project, Grunau’s Oak Creek pipe fabrication shop needed to be reconfigured. A new Plasma Cutter and Victaulic Groover were also on order to be installed in the current space.

The Goal

Create the ideal configuration for both equipment and people in the available Pipe Fabrication Shop space to promote safe and efficient fabrication of required materials.

The Result

In following our Lean 5S process, the first three steps were Sorting and removing unnecessary equipment & material. The second step was Straightening and identifying ideal space for the new equipment. Then Sweeping & cleaning the entire Pipe Fabrication Shop was the third step. Some special projects that evolved from this 5S event were new electrical hook-ups, fabricating additional conveyors & pneumatic lift, and reconfiguring the exhaust system. Other Shop employees & Electricians besides the 5S team helped bring it all together.

With these recent improvements, we’ll be ready to fabricate like never before!